Hi fellows, I hope that everyone healthy,

I have a doubt about to input cost compositions with auxiliary cost compositions in Spider, can someone help me?

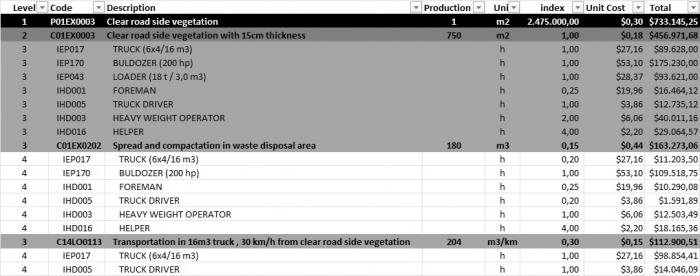

Look below, I have a cost composition for clear road side vegetation from estimate software that give $733.145,25 for 2.475.000m2, i.e. $0,30 / m2.

wysiwyg_imageupload::

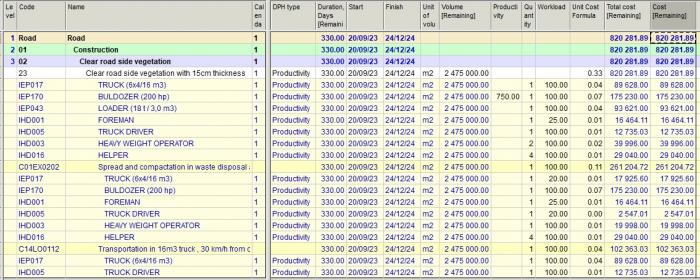

I tried to simulate the same composition in Spider using multi-resources because I thought that is better way, but unfortunately the value is different, $0,33/m2, $820.281,89, I expected it to be exactly the same, but not.

What my mistake? the way is different? is there a viable way forward?

My inttention is to fit a model to control budget and delivery dates for main resources of the project like truck, bulldozers and so on.

Thank you in advance and best regards for all,

Follow the link for files,

https://we.tl/t-GSMYgg3bau

Daniel Morais

Replies